OND LIFT LLC

Ond Lift USA LLC is well established as a leading Lift Tables and Goods lift manufacturer. Ond Lift USA is located in Chicago, IL.

As a company that has specialized in this product for over four decades, we have gained considerable experience and developed the design. Our mission to design and build the highest-quality standard and custom lifts has allowed us to work closely with major industries worldwide. Knowing that working methods will constantly develop, we try to build as much flexibility as possible into the lift design. It is advantageous not to change the lift table when the working practice changes.

Bespoke design, quality and flexibility are our design philosophy…

PRODUCT RANGE

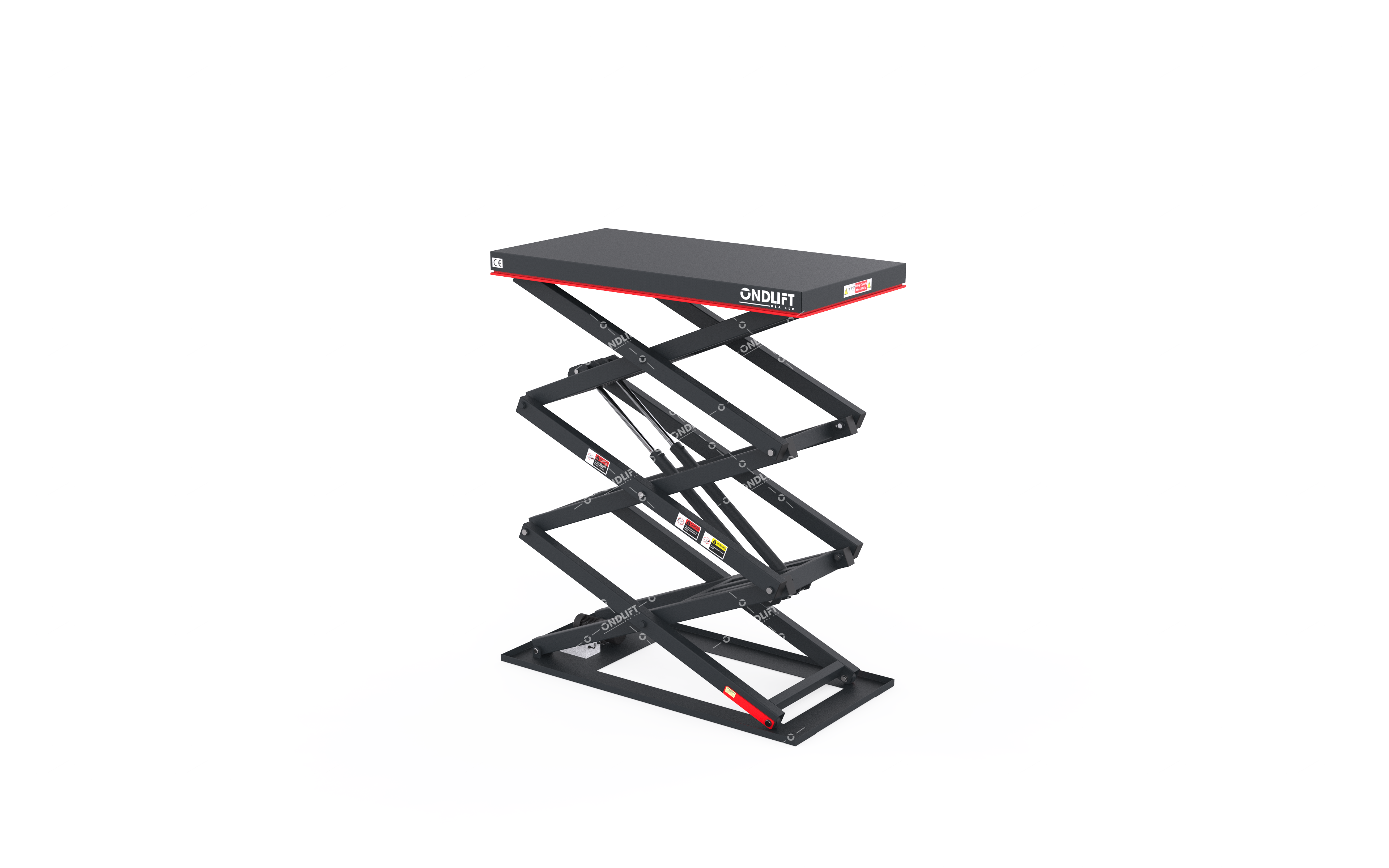

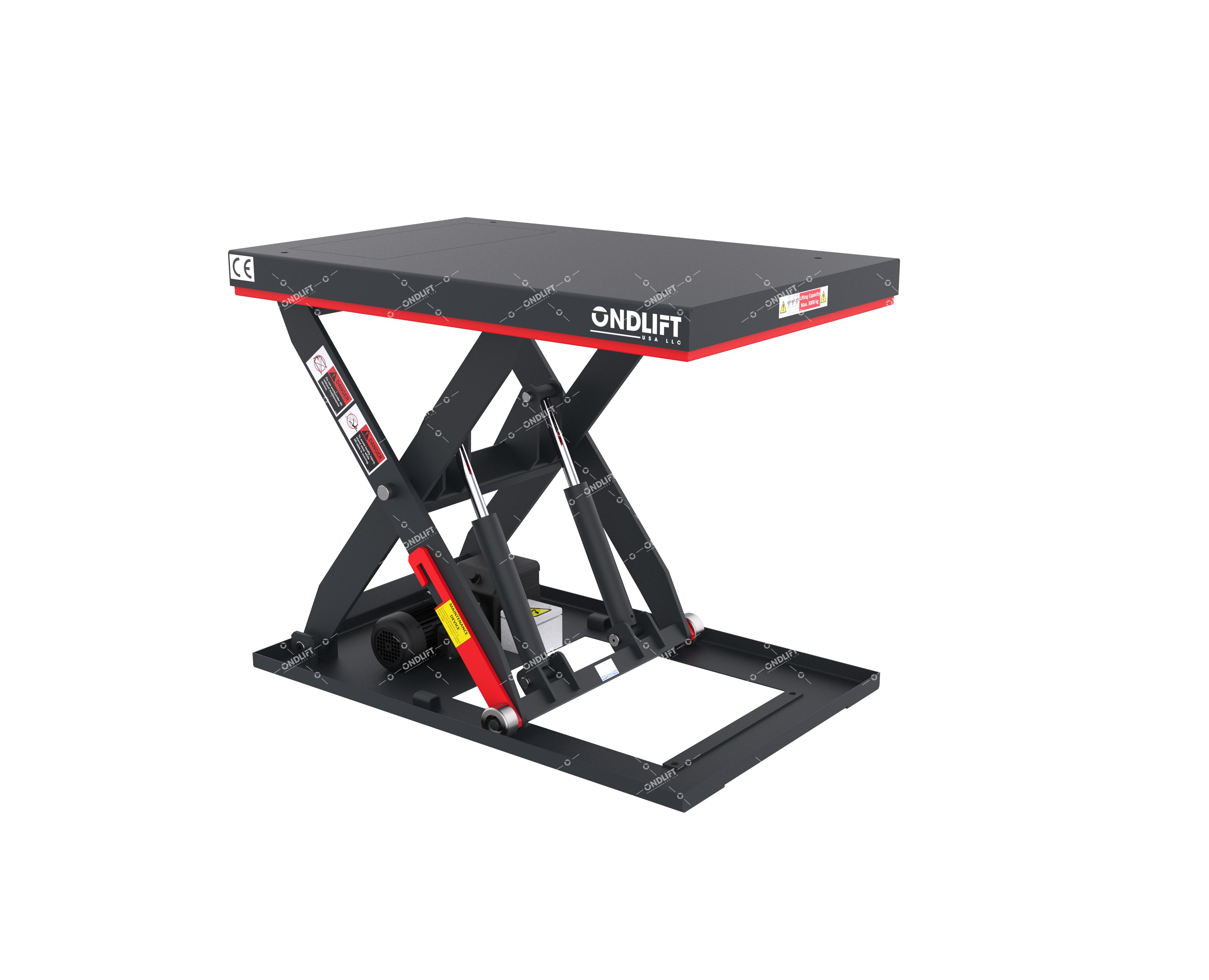

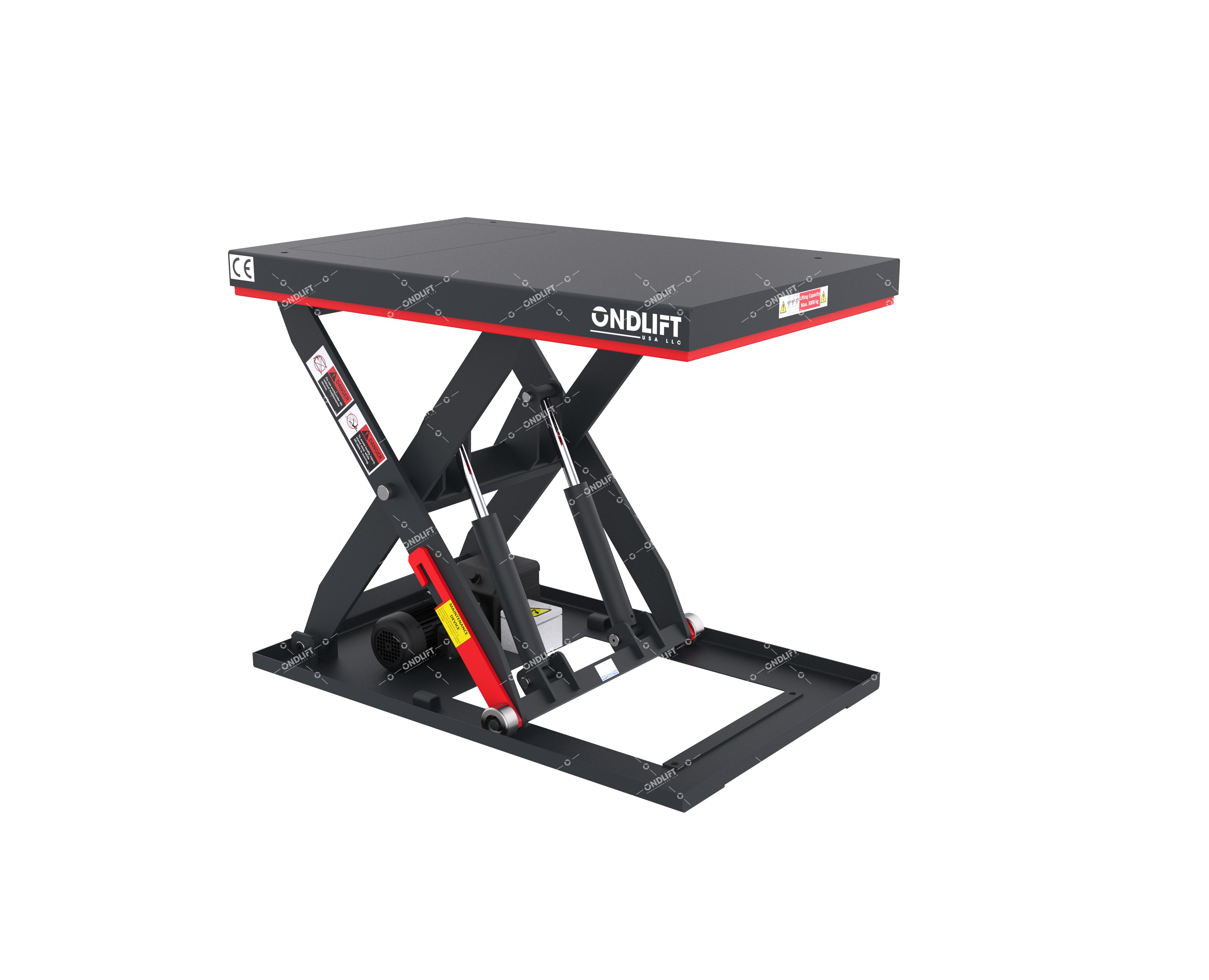

Lift Tables

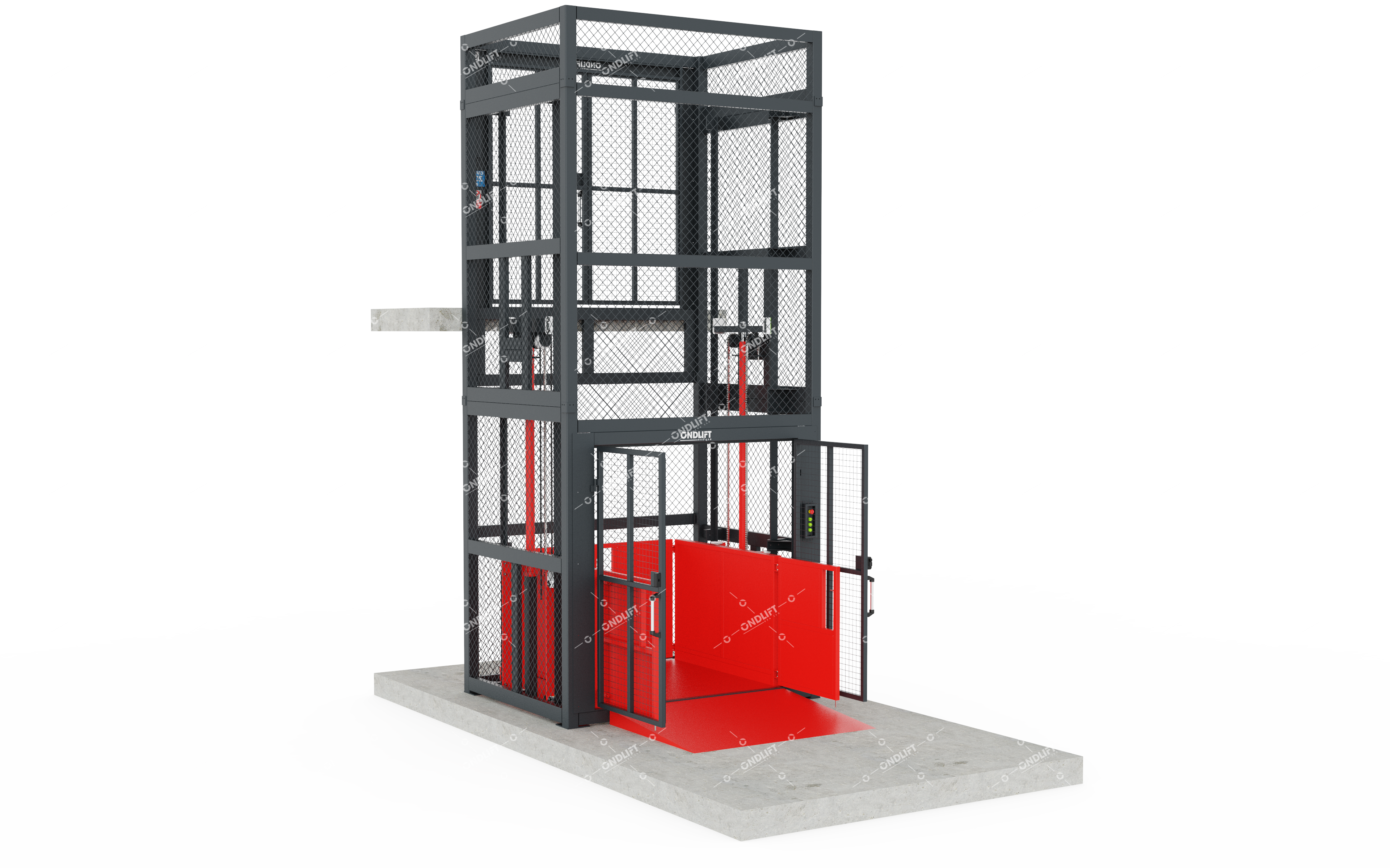

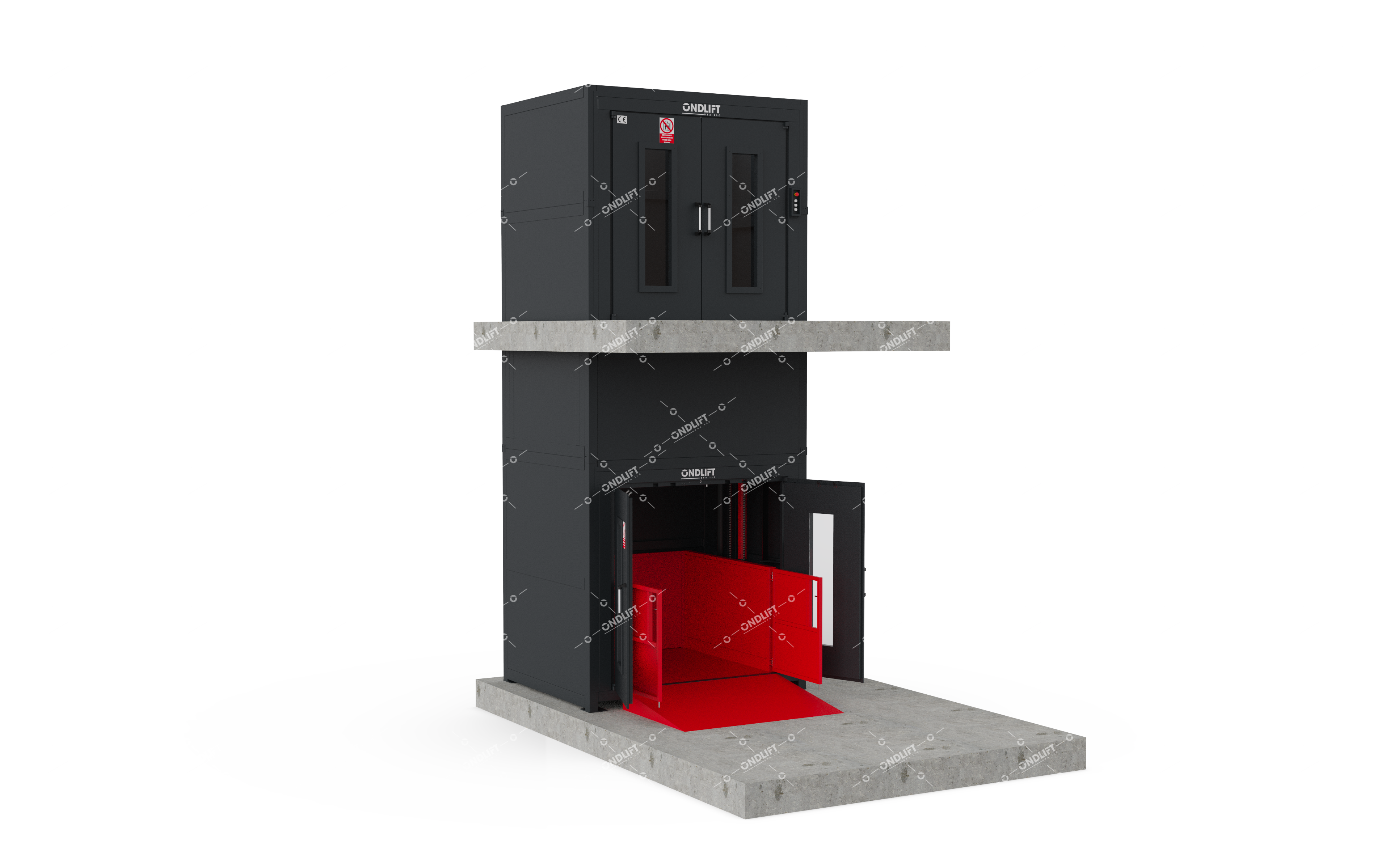

Goods Lift

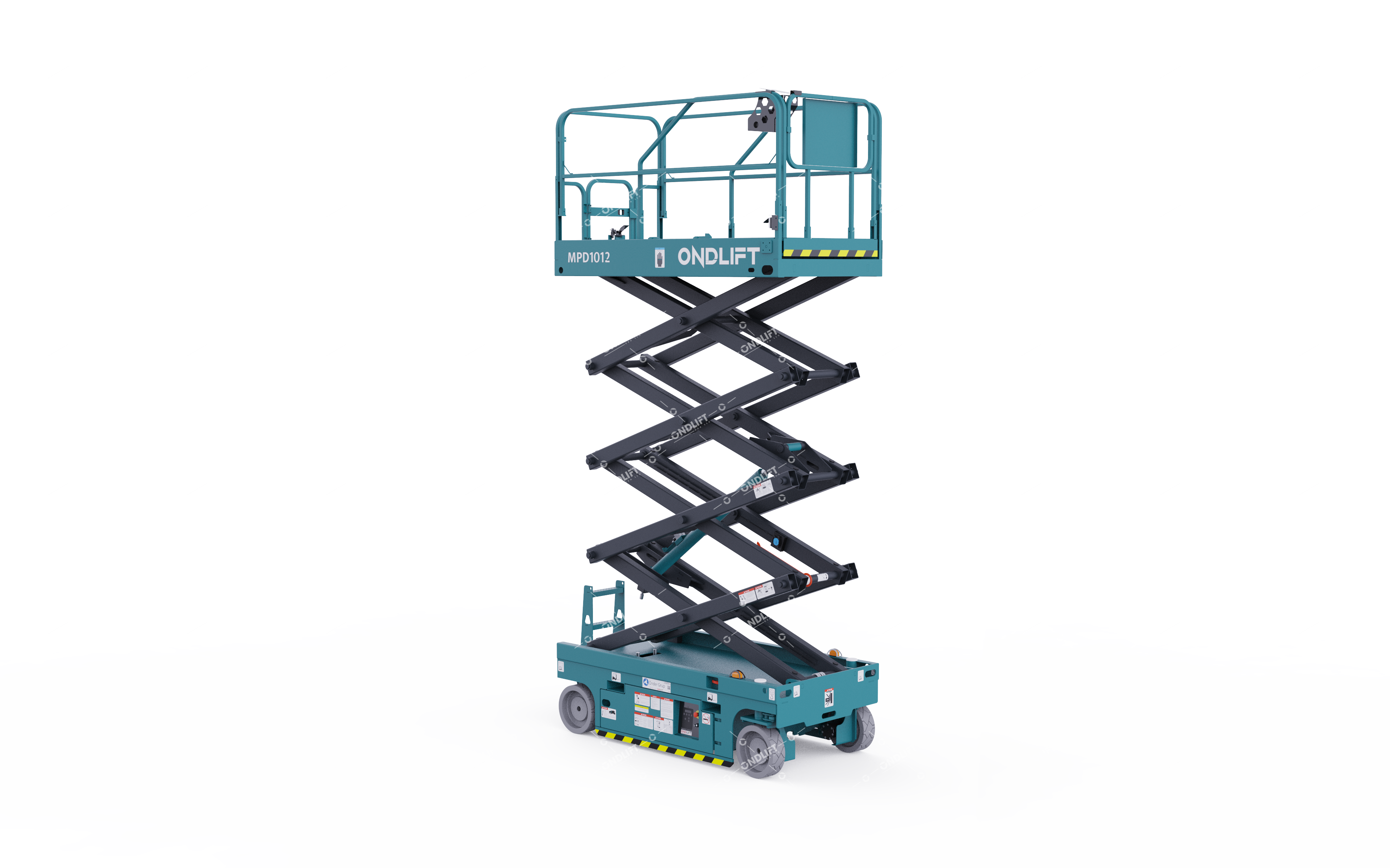

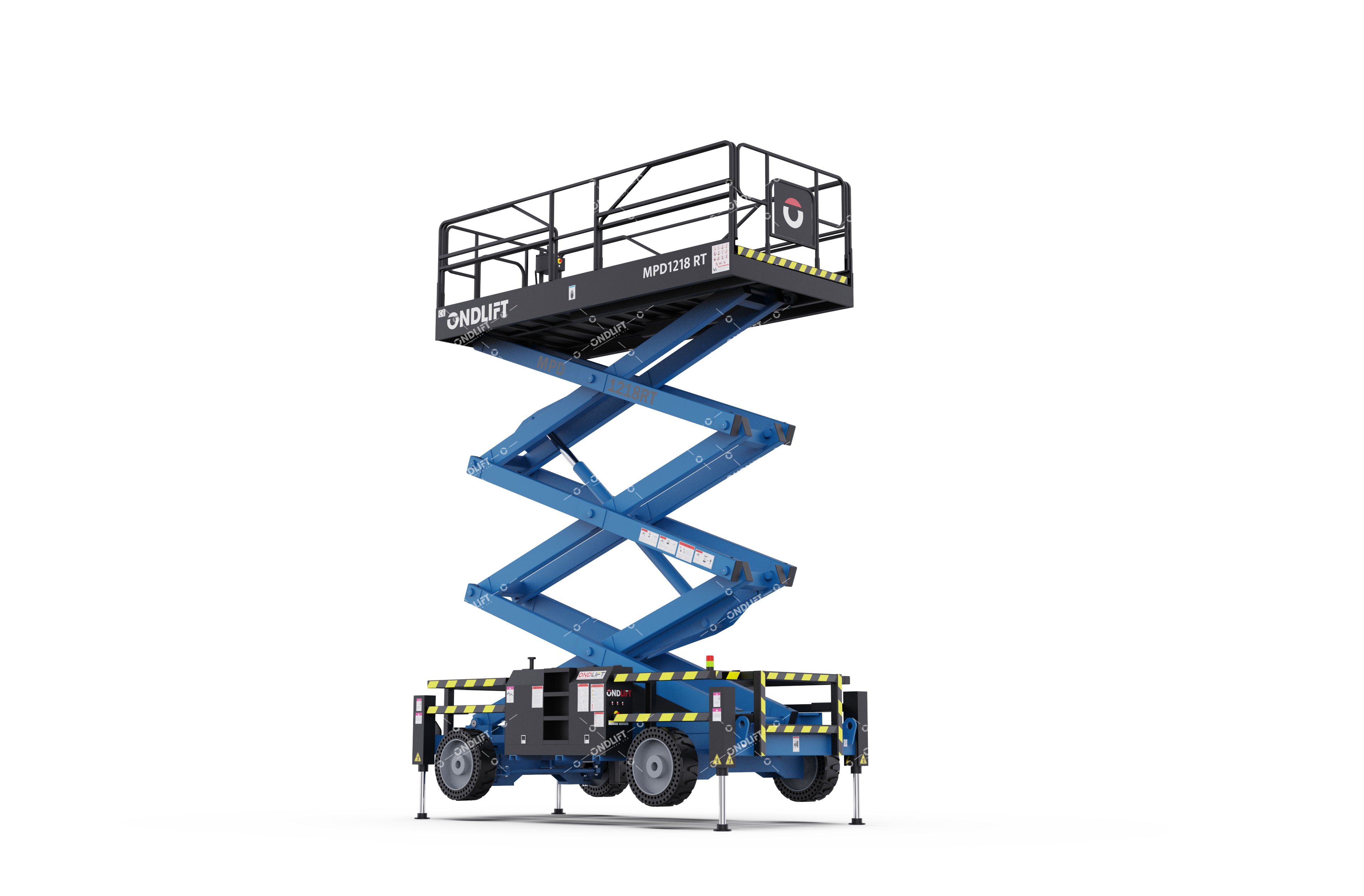

Scissor Lift

Case Studies

- Goods Lift

- Lift Tables

- Scissor Lift

References

Safe Elevation, Smart Solutions: Discover ONDLift’s Articulated Boom Lifts

In industrial environments where efficiency and worker safety go hand in hand, having the right equipment is not a luxury—it’s a necessity. From construction sites to maintenance operations, ONDLift’s Articulated Boom Lifts offer an advanced and reliable solution for working at height with confidence.

With decades of engineering expertise and a deep understanding of industrial challenges, ONDLift designs and manufactures lift systems that combine safety, durability, and ease of use. Whether you’re working indoors or across rough outdoor terrain, ONDLift delivers a product range built to match your project needs.

What Is an Articulated Boom Lift?

An Articulated Boom Lift is a type of aerial work platform that allows one or more operators to safely access elevated and hard-to-reach areas. The lift features jointed arms (booms) powered by hydraulic or electric systems, offering both vertical and horizontal reach. At the end of the boom, a secure basket allows for safe and stable operation at height.

Why Choose ONDLift?

-

✅ Local Expertise, Global Standards: All ONDLift products are manufactured with precision and tested according to international safety certifications (CE, EN standards).

-

✅ Custom Engineering: Whether you need a compact model for warehouse use or a rough-terrain lift for outdoor operations, ONDLift tailors its solutions to your operational environment.

-

✅ Operator Comfort & Safety: Our ergonomic control panels, safety rails, overload protection systems, and emergency shut-offs are all standard—because your team’s safety is non-negotiable.

-

✅ Service & Support: ONDLift provides after-sales technical support, spare parts availability, and operator training to ensure maximum uptime.

Key Advantages of ONDLift Articulated Boom Lifts

-

Precision Maneuvering: The articulated arm design offers superior movement flexibility, making it ideal for working around obstacles or in narrow spaces.

-

Multi-Environment Use: Whether it’s warehouse lighting or building façade maintenance, ONDLift lifts adapt to both indoor and outdoor tasks.

-

Time-Saving Setup: With fast deployment and user-friendly controls, jobs are completed efficiently without complex installation.

-

High Reach & Capacity Options: Models vary in platform height and weight capacity, supporting both light maintenance work and heavy-duty industrial applications.

Where Are ONDLift’s Boom Lifts Used?

-

Construction & Roofing Projects

-

Facility & Electrical Maintenance

-

Glass & Façade Cleaning

-

Event Setup & Lighting Installation

-

Telecommunications & Utility Work

Articulated Boom Lift vs. Lift Table: Which One Do You Need?

| Feature | Articulated Boom Lift | Lift Table |

|---|---|---|

| Purpose | Personnel elevation for working at height | Material lifting and handling |

| Movement | Vertical + Horizontal (via articulated boom) | Vertical only |

| Application Environment | Construction, maintenance, outdoor work | Warehousing, logistics, production lines |

| Platform Type | Secured basket with safety features | Flat surface, not for personnel use |

ONDLift also offers robust Lift Tables for your logistics and load-handling needs—another area where our expertise shines.

Need a Lift for Uneven Terrain?

ONDLift’s Rough Terrain Articulated Boom Lifts are purpose-built for outdoor use in challenging environments. With heavy-duty tires, enhanced ground clearance, and powerful engines, they maintain performance and operator safety even on slopes or gravel.

Get Started with ONDLift Today

Choosing the right lift solution is not just about height—it’s about safety, efficiency, and trust. ONDLift combines all three with industry-leading design and responsive customer service. Whether you’re renting for a short-term project or outfitting your entire operation, ONDLift is your trusted elevation partner.

📞 Contact our expert team today to explore product options, get a free quote, or schedule a demo.

🌐 Visit www.ondlift.com to learn more.

ONDLift to Exhibit at Pharmintech & IPACK-IMA 2025!

We at ONDLift are proud to announce our participation in the upcoming Pharmintech & IPACK-IMA exhibition, taking place in Milan from May 27 to 30, 2025. We will be showcasing our latest innovations in lift table solutions.

Innovative Approach to Lift Tables

ONDLift continues to stand out in the industrial lifting sector by prioritizing quality, safety, and operational efficiency. Our Lift Table solutions are designed to optimize workflows in industries such as food, pharmaceuticals, chemicals, and logistics — where production lines demand precision and reliability.

Why Pharmintech & IPACK-IMA?

As one of Europe’s leading trade shows for processing and packaging technologies, Pharmintech & IPACK-IMA brings together global innovations in machinery, automation, and production systems for the pharmaceutical, cosmetic, food, and chemical industries.

This event offers ONDLift a perfect opportunity to connect with professionals from our target sectors and showcase the advanced solutions we provide.

Focus on Sustainability and Efficiency

At ONDLift, we are committed to delivering not only robust and reliable lift systems but also environmentally conscious solutions. Our energy-efficient lift tables help businesses reduce operational costs while minimizing environmental impact — a win-win for both productivity and sustainability.

Visit Us at the Fair!

📍 Date: May 27–30, 2025

📍 Venue: Fiera Milano, Milan – Italy

📍 Our Stand: E-35 – F-36

📍 Padiglione : 10

We invite you to visit our stand to explore our lift table solutions up close and discuss how we can support your projects with tailored systems. Let’s shape the future of industrial lifting together!

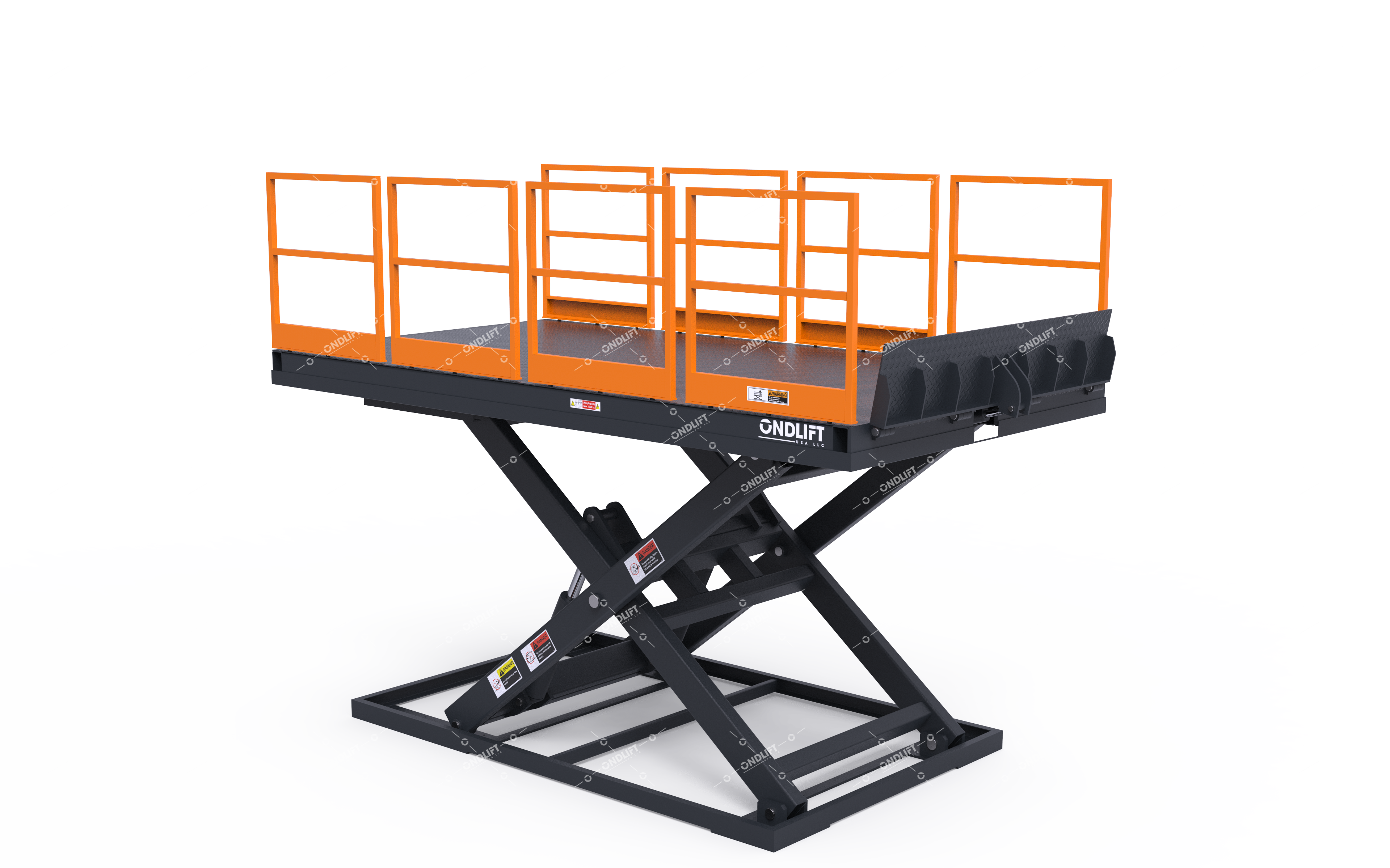

How to Get Maximum Performance with a Loading Dock Table

In today’s fast-paced industrial and logistics environments, the efficiency and safety of loading and unloading operations play a key role in overall productivity. Businesses are increasingly looking for smart, durable and high-performance solutions to bridge the gap between delivery vehicles and warehouse floors. This is where the Loading Dock Table, designed for seamless material transfer, becomes an essential asset. As a trusted manufacturer, OND Lift offers advanced Loading Dock Table systems that combine precision engineering, compliance with international standards and cross-industry adaptability. In this comprehensive guide, we answer the most frequently asked questions about these systems and explain how they can significantly improve your operations.

What Is a Loading Dock Table and What Is It Used For?

A Loading Dock Table is a hydraulic scissor lift platform designed to eliminate height differences between trucks or trailers and warehouse floors during loading and unloading operations. It ensures that materials are transferred safely and efficiently by aligning vehicle bed levels with dock surfaces. These systems not only save time but also reduce workplace accidents, increasing operational safety. With OND Lift’s high manufacturing standards, Loading Dock Tables provide maximum efficiency and safety in material transfer processes across a variety of industries.

What Are the Safety Features?

At OND Lift, safety is always our top priority. Our Loading Dock Tables are equipped with vital safety components, including hydraulic hose burst valves, emergency stop buttons, overload protection sensors, and anti-slip surface coatings. In addition, edge barriers, mechanical maintenance locks, and photoelectric sensors are integrated to protect both the operator and the load. All of our systems comply with CE, EN 1570-1, and OSHA standards, ensuring full legal and functional compliance in both European and American markets.

How Is the Installation Process Carried Out?

OND Lift makes installation fast and simple with expert engineering support. First, a technical assessment is conducted at the site to determine infrastructure requirements—whether a pit-mounted or surface-mounted system is appropriate. Once the base is prepared, the product is shipped and installed by connecting the hydraulic and electrical components. After comprehensive functional and safety testing, we provide hands-on training to ensure safe operation. For our U.S. customers, installation services are supported through our local technical partners.

How Does the Purchasing Process Work?

Purchasing a Loading Dock Table from OND Lift is straightforward and transparent. It begins with defining your operational needs, such as load capacity, platform size, and usage conditions. Based on this, we prepare custom technical drawings and a price offer. The system is then shipped, installed, and commissioned with on-site training included. Throughout the process, we maintain clear communication and technical documentation.

What Are the Advantages of Loading Dock Tables?

OND Lift’s Loading Dock Tables offer more than just load transfer—they enhance efficiency and safety across the entire workflow. These systems reduce manual effort, speed up loading times, and integrate seamlessly with forklifts and pallet jacks. Their heavy-duty steel structures provide long-term durability with minimal maintenance. Furthermore, customized designs can be adapted to space-constrained environments or specific application scenarios, giving your facility a strategic operational edge.

Where Are Loading Dock Tables Used?

Our systems are widely used in logistics hubs, manufacturing plants, food and beverage facilities, automotive factories, retail distribution centers, and chemical and pharmaceutical production lines. Whether it’s receiving goods in a warehouse, transferring parts in a factory, or managing outbound logistics in a retail operation, OND Lift provides tailored solutions to meet your specific industry needs.

Maintenance and Safety Tips for Maximum Performance

To ensure long-lasting performance, regular maintenance of your Loading Dock Table is essential. OND Lift provides maintenance schedules to guide operators. Weekly visual inspections should be conducted to check hydraulic hoses, bolts, and surface wear. Monthly checks should include hydraulic oil levels and system responsiveness. Annual inspections by authorized service teams should cover mechanical and electrical systems in detail. Additionally, periodic safety training for operators reduces risks and extends the equipment’s operational lifespan.

How to Boost Operational Efficiency with a Loading Dock Table

A Loading Dock Table is not just a tool—it’s a key part of your logistics strategy. OND Lift’s solutions are designed to improve workflow through features such as remote control operation, automatic level sensing, and forklift compatibility. Modular designs that support multi-bay loading points prevent process bottlenecks, while optional smart sensor integrations enable real-time monitoring and data collection for performance optimization. These systems help businesses save time, reduce labor costs, and increase throughput across all material handling stages.